In plate cutting operations, CAM software performs another critical function known as “nesting.” Nesting is defined as the efficient placement of multiple part geometries onto a given surface area. Plasma cutting software is intended to simplify the machine operator’s job and increase productivity. If this is your plasma cutting software, this includes parameters such as arc current, voltage, gas preflow, cut flow settings, cut speeds, cut heights, pierce heights, and more. Some types of CAM software can control and automatically set virtually every aspect of the cutting operation.

For example, it may check the geometry for errors, apply kerf compensation, set the cut sequence, add leads, and apply other advanced cutting parameters.

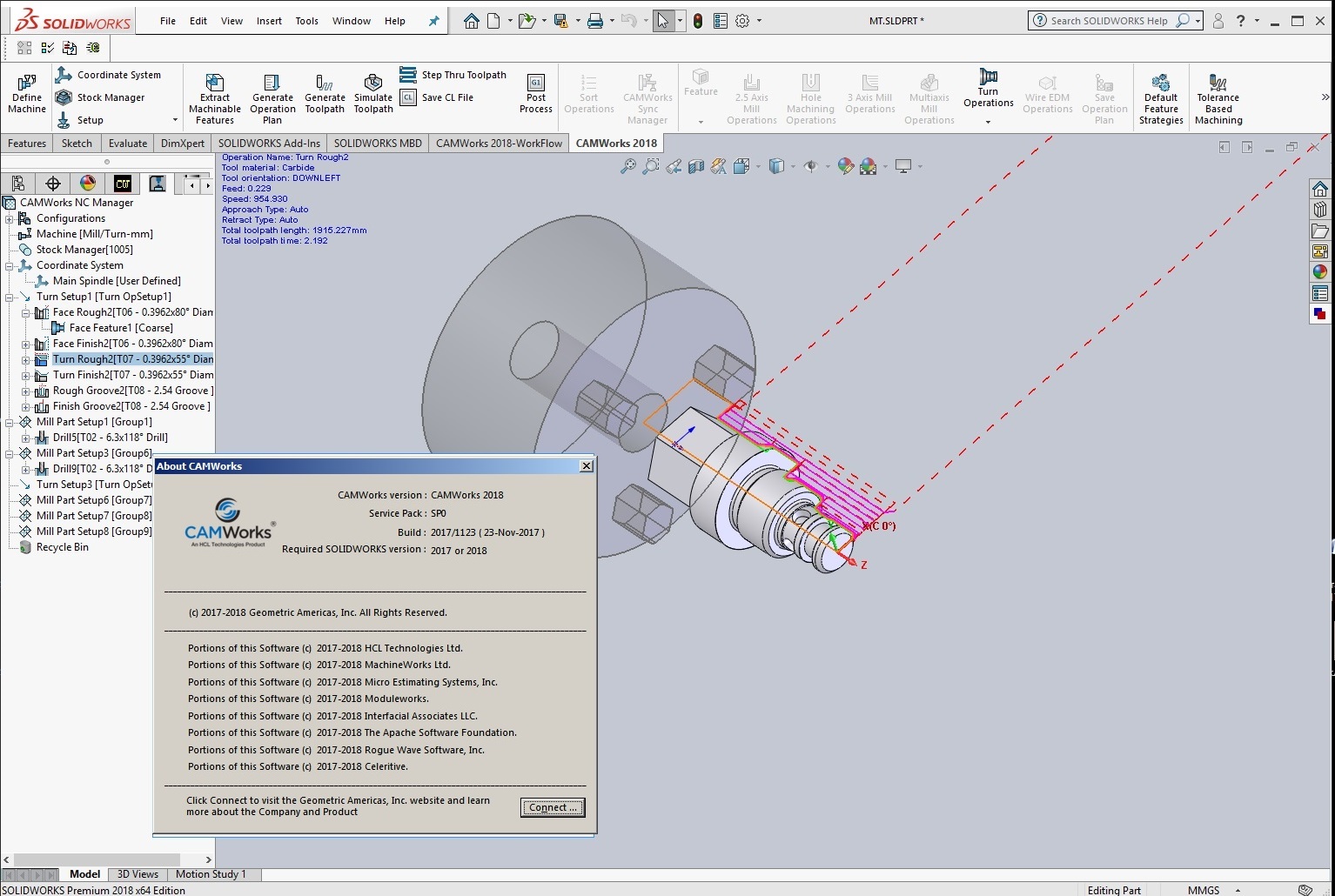

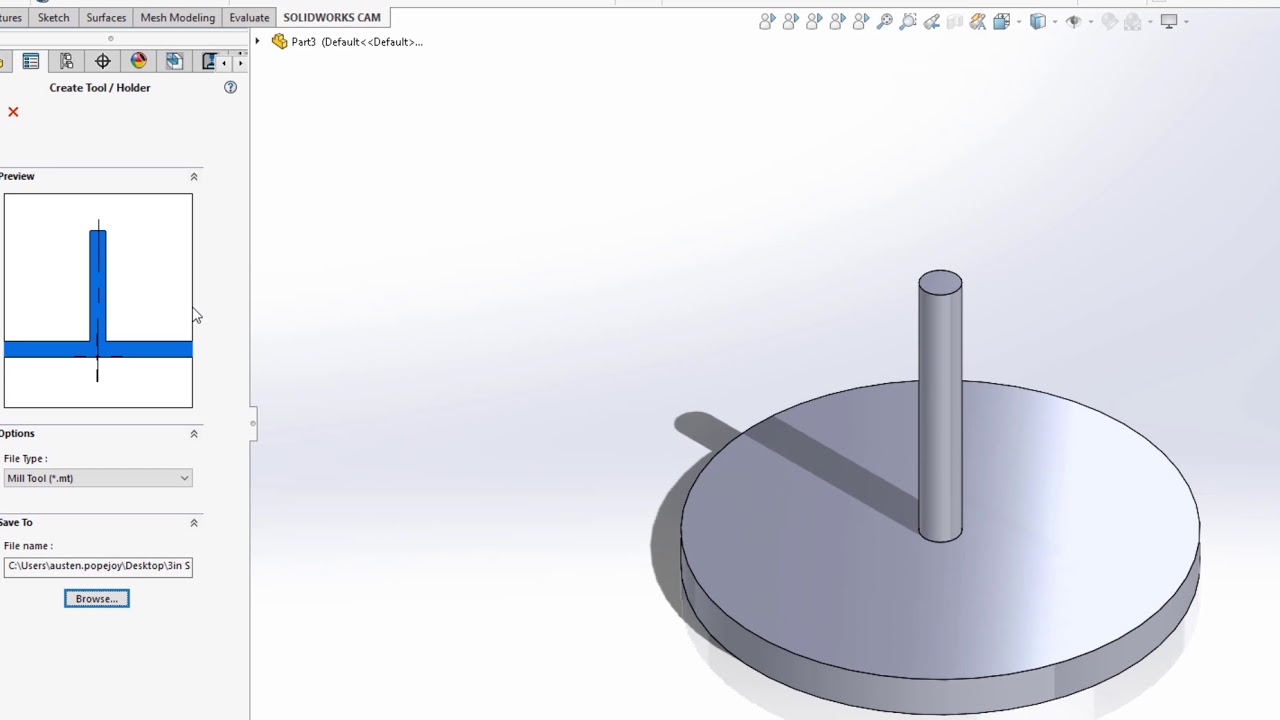

The CAM (Computer Aided Manufacturing) part of the software then takes over to directly communicate with and control the machine tools used in the manufacturing process.” It includes most CNC machines used in manufacturing today.ĬAM plasma cutting software prepares the CAD file for cutting and machining. This results in a detailed 2D or 3D model. How CAD/CAM worksĬAD, short for “computer aided design,” uses computer programs to draw the exact part or object that is needed. This combination solution provides all of the necessary functionality to complete the job, from CAD concept, to part preparation, to nesting, to numeric code output. While there are many different types of CAM software used in industry today, CAD/CAM nesting software is typically used for programming mechanized flat plate cutting, offering fabricators and manufacturers a single software solution for all of their profile cutting needs – including plasma, laser, waterjet, and oxyfuel. CNC software is normally not included in this package because it is more dependent on the cutting machine or CNC that is being used.ĬAM software helps drive the manufacturing process. While it is possible to buy each type of software separately, today most software providers combine the first three types of software-CAD, CAM, and Nesting-into one package.

0 kommentar(er)

0 kommentar(er)